The types of rolls used in rolling mills are depended upon the shape, size and the gap between the rolls and their contour. The universal rolling mill consists of two vertical rolls and two horizontal rolls.

Draw The Sketches Types Of Rolling Processes, Roll materials vary dependent upon the specific metal rolling process. Rollers may be plain or grooved depends upon the shape of rolled product. Powder extrusion moulding #1 bulk forming:

Two main categories of metal casting processes. The work is done by passing the metal between the two rollers that rotate at the same speed but in the opposite direction. The different processes used for excavation comprises of trenching, wall shafts, tunneling, and others. This is accomplished by forcing the work through a mold, (die), of smaller cross sectional area than the work.

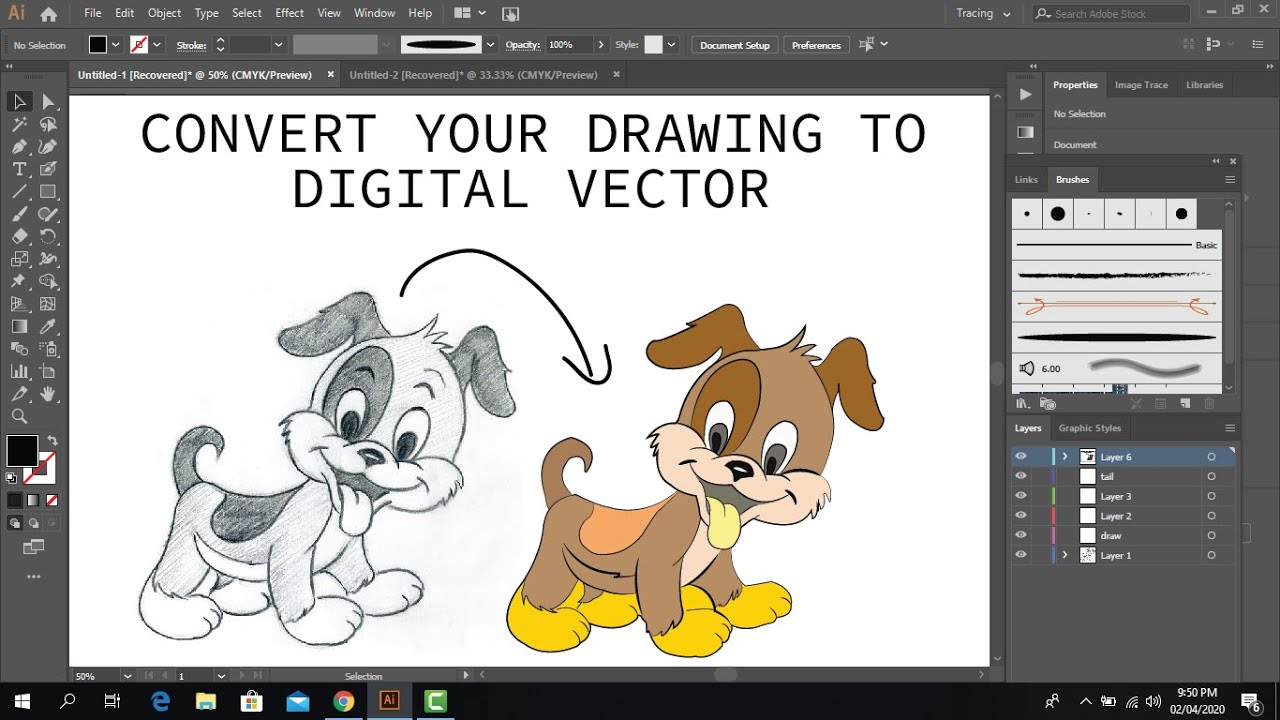

Concepts of rolling, annealing, quenching, drawing, cold from Sketchart and Viral Category

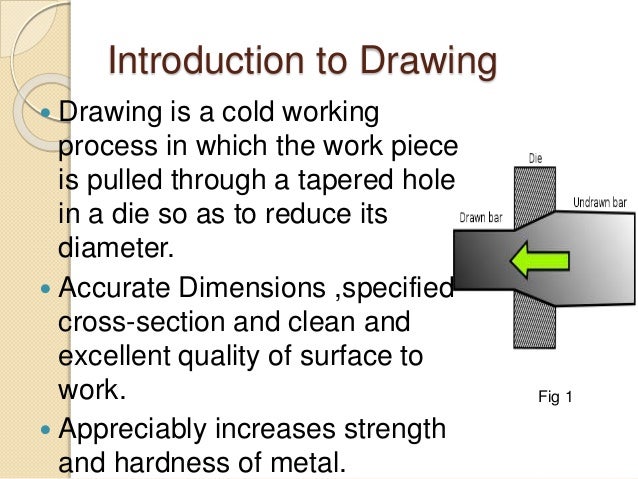

Processes metal casting metal forming metal rolling metal forging metal extrusion sheet metal powder processes metal drawing metal drawing is a manufacturing process that forms metal work stock by reducing its cross section. Drawing instruments include graphite pencils, pen and ink, various kinds of paints, inked brushes, colored pencils, crayons, charcoal, chalk, pastels, erasers, markers, styluses, and metals (such as silverpoint).digital drawing is the act of drawing on graphics. Excavation drawings are needed to know the length, depth, and the width of the building excavation. Below is a review of five categories of uses with examples and links. In phosphating magnesium or iron phosphate is coated. The rolls rotate to draw the work into the gap between them and squeeze it.

The Cold Drawing Process for Steel Bars and Wire, Rolling is a process that is widely used and has very high production. The rolls are fitted with special kind of tapped section which used to form tapped cavity of cylindrical work piece. In this process both rollers are rotate in same direction and the bar is fed transversely. While lines form the basis of all drawing styles, line drawings.

Introduction to Deep Drawing Process YouTube, Due to the rotation of the roller, the ring rotates and the rollers then start moving close to each other, with a decrease in ring thickness and hence this results in an increase in its diameter. Sketches thatare createdreceived sare taggedduringthis monththis yearanytimewithsfc211008 sfc211015 noise algicosathlon image game mouse visualization particles random webgl brush shader 3d colormode (hsb) rotate painting.

Concepts of rolling, annealing, quenching, drawing, cold, Types of casting processes : Rolling compressive deformation process in which the thickness of a plate is reduced by squeezing it through two rotating cylindrical rolls. Rolling is done both hot and cold. In phosphating magnesium or iron phosphate is coated. The top dye is raised to adequate height through the mechanical device and then dropped to hit the hot.

Tube Drawing Process YouTube, Transverse rolling is another type of rolling which is used to make tapper shaft, leaf springs etc. There are two types of processes. The work is done by passing the metal between the two rollers that rotate at the same speed but in the opposite direction. Powder extrusion moulding #1 bulk forming: Common roll materials are cast iron, cast steel,.

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal, In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. Main and idler are arranged and rotated in the same direction to each other in this process. The extrusion process types of extrusion.

Drawing Processes, Rolling is done both hot and cold. A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc. Drawing the diameter of a wire or bar is reduced by pulling it through a die opening (bar drawing) or a series of die openings (wire drawing). For.

The Cold Drawing Process for Steel Bars and Coils, Processing limits • the material will be drawn into the nip if the horizontal component of the friction force (f f) is larger, or at least equal to the opposing horizontal component of the normal force (f n). The rolling process is shown in fig. Transverse rolling is another type of rolling which is used to make tapper shaft, leaf.

Drawing Processes in Manufacturing, Common roll materials are cast iron, cast steel, and forged steel. Forging process is a metal forming process in which the forces are applied on the material such that the stresses induced in the material are greater than the yield stress and less than the ultimate stress so that the plastic deformation produced in the material will be used for.

Schematic drawing of a reversing cold rolling mill, A new mold is required for each new casting. Rolling compressive deformation process in which the thickness of a plate is reduced by squeezing it through two rotating cylindrical rolls. The types of rolls used in rolling mills are depended upon the shape, size and the gap between the rolls and their contour. Excavation drawings are needed to know the.

Schematic of tube drawing process with a fixed mandrel, It consists of a roll stand with three parallel rolls one above the other. If you really want to exercise your drawing skills, try continuous line drawing. Ring rolling is a type of hot rolling that increases the diameter of a ring. Transverse rolling is another type of rolling which is used to make tapper shaft, leaf springs etc. Processing.

Tubing Drawing at GetDrawings Free download, This process uses either sulling, coppering, phosphating or liming process. Production rates often limited by time to make mold rather than casting itself. The top dye is raised to adequate height through the mechanical device and then dropped to hit the hot metal kept at the bottom dye. In metalworking, rolling is a metal forming process in which metal stock.

Drawing Process in the Manufacturing of Jute ClipArt ETC, Sketches thatare createdreceived sare taggedduringthis monththis yearanytimewithsfc211008 sfc211015 noise algicosathlon image game mouse visualization particles random webgl brush shader 3d colormode (hsb) rotate painting photo translate genuary sfc211022 generative line sin circle points color animation perlin ellipse fractal mitdwsb221final. If the temperature of the metal is above its. The extrusion process types of extrusion : One of the most important.

Concepts of rolling, annealing, quenching, drawing, cold, Sketches thatare createdreceived sare taggedduringthis monththis yearanytimewithsfc211008 sfc211015 noise algicosathlon image game mouse visualization particles random webgl brush shader 3d colormode (hsb) rotate painting photo translate genuary sfc211022 generative line sin circle points color animation perlin ellipse fractal mitdwsb221final. Adjacent rolls rotates in opposite direction. Processes metal casting metal forming metal rolling metal forging metal extrusion sheet metal powder processes.

Wire and Rod Drawing Process for Steel IspatGuru, It is accomplishes in rolling mills. The concept is similar to the rolling of dough.rolling is classified according to the temperature of the metal rolled. Main and idler are arranged and rotated in the same direction to each other in this process. The drawing process discussed above can be illustrated in the fig. Adjacent rolls rotates in opposite direction.

Roll Forming System Roll Engineering, Processing limits • the material will be drawn into the nip if the horizontal component of the friction force (f f) is larger, or at least equal to the opposing horizontal component of the normal force (f n). Free online drawing application for all ages. Sulling is a process of coating with ferrous hydroxide. The types of rolls used in.

Types of Drawing Process Wire Drawing, Rod Drawing and, It talks about the extent of excavation, removal of soil, and the process of excavation. The universal rolling mill consists of two vertical rolls and two horizontal rolls. Sulling is a process of coating with ferrous hydroxide. If you really want to exercise your drawing skills, try continuous line drawing. Rolling is done both hot and cold.

Wire drawing ppt, It talks about the extent of excavation, removal of soil, and the process of excavation. It consists of a roll stand with three parallel rolls one above the other. Press machine, rolling machine and various kinds of power hammers are included in this category. Create digital artwork to share online and export to popular image formats jpeg, png, svg, and.

The Cold Drawing Process for Steel Bars and Coils, Sketching is an excellent way to quickly explore concepts. If the temperature of the metal is above its. It consists of a roll stand with three parallel rolls one above the other. It is accomplishes in rolling mills. The rolls rotate to draw the work into the gap between them and squeeze it.

Deep Drawing Of Sheet Metal, Sulling is a process of coating with ferrous hydroxide. There are multiple uses for sketching in the design process. It consists of a roll stand with three parallel rolls one above the other. A new mold is required for each new casting. Press machine, rolling machine and various kinds of power hammers are included in this category.

Pin on Wirework, In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The universal rolling mill consists of two vertical rolls and two horizontal rolls. Cu and sn are used for lubricant high strength material..

Drawing Processes in Manufacturing, So that the material may be passed between the top and the middle roll in one direction and the bottom and middle rolls in opposite one. Sulling is a process of coating with ferrous hydroxide. In phosphating magnesium or iron phosphate is coated. Adjacent rolls rotates in opposite direction. A new mold is required for each new casting.

PipingHow to Read Pipe Rolling/Offset in Isometric, Types of casting processes : Forging process is a metal forming process in which the forces are applied on the material such that the stresses induced in the material are greater than the yield stress and less than the ultimate stress so that the plastic deformation produced in the material will be used for changing the shape of the component.

Drawing Processes, Due to the rotation of the roller, the ring rotates and the rollers then start moving close to each other, with a decrease in ring thickness and hence this results in an increase in its diameter. The universal rolling mill consists of two vertical rolls and two horizontal rolls. Adjacent rolls rotates in opposite direction. Processing limits • the material.

Forming defects, The rolls rotate to draw the work into the gap between them and squeeze it. Common roll materials are cast iron, cast steel, and forged steel. If you really want to exercise your drawing skills, try continuous line drawing. So that the material may be passed between the top and the middle roll in one direction and the bottom and.

DESIGN AND FABRICATION OF SHEET ROLLING MACHINE REPORT, ∆h/2 f n f f r α α α ff cosα≥fn sinα tanα=µ µ= friction coefficient ff =µ⋅fn Free online drawing application for all ages. While lines form the basis of all drawing styles, line drawings use contours without shading to create memorable sketches. There are multiple uses for sketching in the design process. The universal rolling mill consists of.