We made this as an example of how you can use machine learning in fun ways. It is convenient to use and easy to hold for any kind of operator.[4] there are.

A Can Filler Machine Plc Sketch Drawing, Turing drawings uses randomly generated turing machines to produce drawings on a canvas, as a form of generative art. Using a plc, however, we can program as many contacts as we wish for each “x” input without adding additional hardware, since each input and each output is nothing more than a single bit in the plc’s digital memory (either 0 or 1), and can be recalled as many times as necessary. But in this system different operation are performed by software.

Figure 1b shows the result. The highest machine speed attainable is determined by the weighing mechanism. This is the check it out font from here on makers gonna learn. Exploded view drawing of a machine.

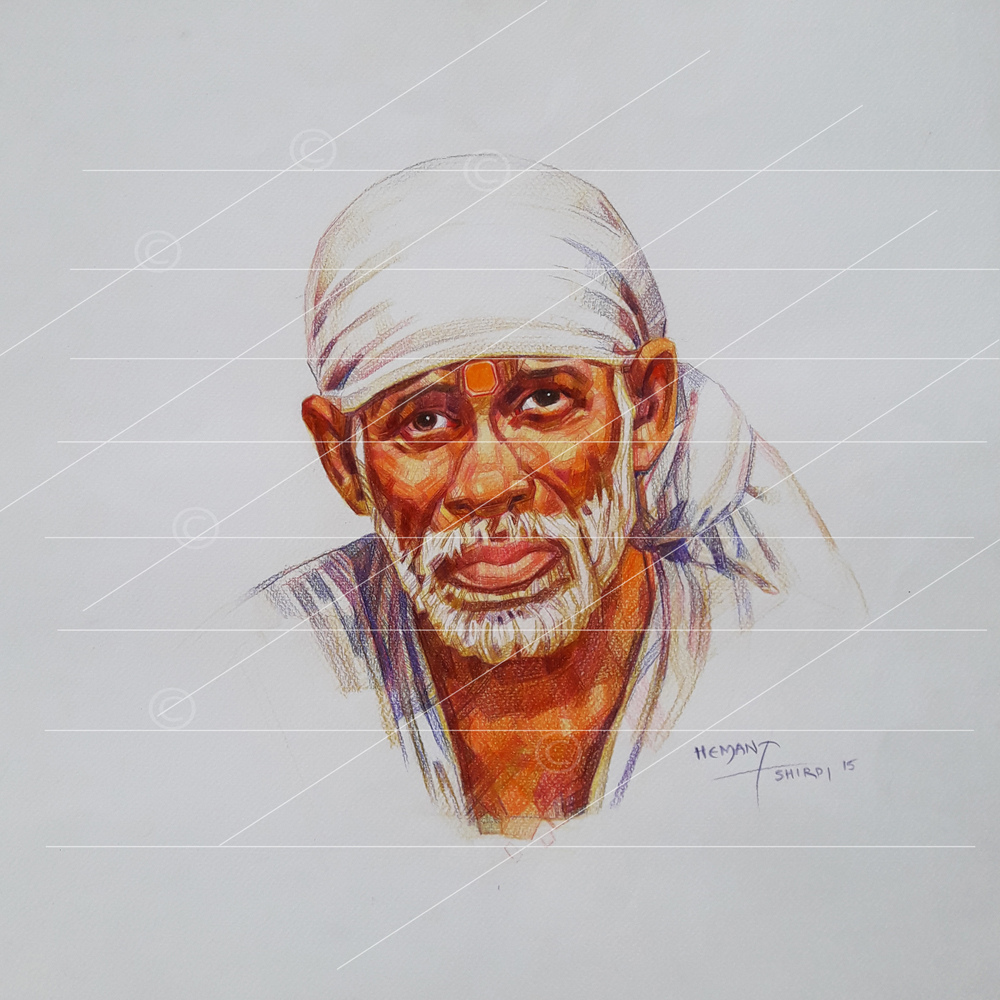

Automated Bottle Filling System | Semantic Scholar from Sketchart and Viral Category

7 best electrical drawing software. Create digital artwork to share online and export to popular image formats jpeg, png, svg, and pdf. This plc can support upto thousands of i/os. Wordsun.com) we can redraw this diagram in a different way, using two vertical lines to represent the input power rails and stringing the rest of the circuit between them. But, it does tend to become more complex. If you simply change from a cut line to a draw line for this font, your cricut will simply draw the outline of each letter.

-1, Use the best professional electrical drawing software of edraw and make. Turing drawings uses machines that operate on a finite 2d grid, where each grid cell can contain one symbol which corresponds to a color value. Figure 5 below shows a schematic diagram for a plc based motor control system, similar to the previous motor control example. 1.2.3.2 detailed assembly.

2, The speed of packaging is increased thus resulting in more production and business. Of course, it doesn’t always work. The shape you see is the combined output of the controls below. We used proximity switch here because the filling has to be started when the box placed in correct position. Free online drawing application for all ages.

Automatic Empty Bottle Detection Using Plc Logic | Instrumentation Tools, Here are the top 7 electrical drawing software which you can use quickly and easily. Caravaggio is a drawing machine able to replicate a digital image using a pen and a continuous line. The shape you see is the combined output of the controls below. The present machines are that it can fill only a particular type of containers of.

Plc Program For Continuous Filling Operation | Plc Example Programs, To get started, we’re choosing a fairly large chunky font. Automatic bottle filling machines are most commonly used in beverages and soft drink industries. Wordsun.com) we can redraw this diagram in a different way, using two vertical lines to represent the input power rails and stringing the rest of the circuit between them. Programmable logic controller operates similar to the.

Automatic Oil Bottle Filling Machine Piston Linear Filler - China Oil Filling Machine, Filling Machine | Made-In-China.com, Turing drawings uses randomly generated turing machines to produce drawings on a canvas, as a form of generative art. Figure 1b shows the result. It is convenient to use and easy to hold for any kind of operator.[4] there are. Polar drawing machine built with fischertechnik and arduino. But, it does tend to become more complex.

Automated Bottle Filling System | Semantic Scholar, Assembly drawing of a machine. With the help of edrawmax, you can create professional electric drawings, whether you are an electrician, engineer, programmer, or builder. The present machines will be that it can fill only a particular type of containers of specific volume and capping the bottle automatically. This machine can used in different industries like medicine, oil, chemical etc..

Plc Ladder Diagram Bottle Filling Plant - Youtube, Figure 5 below shows a schematic diagram for a plc based motor control system, similar to the previous motor control example. • control over the cross jaw along the vertical plane provides additional bag making possibilities. If the page gets too slow, turn some of the parameters down. To develop a filling machine which can fill different volume of bottles.

Automatic Bottle Filling & Capping Machine Using Plc | Ladder Logic, Diagram, Electrical Wiring, Assembly drawing of a machine. Of course, it doesn’t always work. The workpiece starts moving on the left side and moves to the right when the start button is pressed. 7 best electrical drawing software. We have converted your account to an organization!

Programmable Logic Controller For Bottle Filling Machine, We have converted your account to an organization! The diagram shows the circuit for switching on or off an electric motor. Mostly plcs are used for automatic bottle filling machines, but you can make a very basic and versatile bottle filler using an arduino.you can program the arduino to automatically. We used proximity switch here because the filling has to.

Automatic Bottle Filling System Using Plc - Instrumentationtools, This can used in different industries like medicine, oil, chemical etc. It is convenient to use and easy to hold for any kind of operator.[4] there are. Press h or ~ to hide the controls. In this tutorial, we are talking all about drawing and writing with your cricut machine! Create digital artwork to share online and export to popular.

Automatic Bottle Filling System Using Arduino, Mostly plcs are used for automatic bottle filling machines, but you can make a very basic and versatile bottle filler using an arduino.you can program the arduino to automatically. Work with many painting tools online, it�s a free online paint tool. It is convenient to use and easy to hold for any kind of operator.[4] there are. The shape you.

Plc Implementation Of The Bottle-Filling Application, Programmable logic controller is a microprocessor based programming technique, which is used to perform many functions in industrial process. In this tutorial, we are talking all about drawing and writing with your cricut machine! The speed of packaging is increased thus resulting in more production and business. Exploded view drawing of a machine. 1.2.3.2 detailed assembly drawing it is usually.

Automatic Bottle Filling System Using Plc - Instrumentationtools, You draw, and a neural network tries to guess what you’re drawing. Programmable logic controller is a microprocessor based programming technique, which is used to perform many functions in industrial process. Materials and methods flow chart of assembly of the proposed filling machine is shown in fig.1. Figure 5 below shows a schematic diagram for a plc based motor control.

![Pdf] Automatic Liquid Filling To Bottles Of Different Height Using Programmable Logic Controller | Semantic Scholar](https://i2.wp.com/d3i71xaburhd42.cloudfront.net/a998d083edd95d2eafad5f3f43f8026c711e9dd6/2-FigureI-1.png “Pdf] Automatic Liquid Filling To Bottles Of Different Height Using Programmable Logic Controller | Semantic Scholar”)

Pdf] Automatic Liquid Filling To Bottles Of Different Height Using Programmable Logic Controller | Semantic Scholar, Autodraw pairs machine learning with drawings from talented artists to help you draw stuff fast. The workpiece starts moving on the left side and moves to the right when the start button is pressed. Using a plc, however, we can program as many contacts as we wish for each “x” input without adding additional hardware, since each input and each.

Plc Program For Automatic Bottle Rejection System | Plc Ladder Logics, Using a plc, however, we can program as many contacts as we wish for each “x” input without adding additional hardware, since each input and each output is nothing more than a single bit in the plc’s digital memory (either 0 or 1), and can be recalled as many times as necessary. To get started, we’re choosing a fairly large.

Automatic Bottle Filling & Capping Machine Using Plc | Ladder Logic, Diagram, Electrical Wiring, Filling line for edible oil in pet bottles and pe cans. The forward and reverse pushbuttons provides a means of starting the. • control over the cross jaw along the vertical plane provides additional bag making possibilities. Using a plc, however, we can program as many contacts as we wish for each “x” input without adding additional hardware, since each.

Plc Implementation Of The Bottle-Filling Application, You can now invite others to collaborate on your content. Work with many painting tools online, it�s a free online paint tool. If you liked this article, then please subscribe to our youtube channel for plc and scada video tutorials. We made this as an example of how you can use machine learning in fun ways. We used proximity switch.

Semi Automatic Auger Powder Fillers | Powder Filling Machines, It is convenient to use and easy to hold for any kind of operator.[4] there are. In rack type plc all the components of the plc are as separate modules and are assembled to form one unit by mounting the individual components on a rack. Mouse over them to see what they do. To get started, we’re choosing a fairly.

2, You can now invite others to collaborate on your content. But, it does tend to become more complex. Find out more in this blog post. But the more you play with it, the more it will learn. Automatic bottle filling machines are most commonly used in beverages and soft drink industries.

Plc-Program-For-Bottle-Filling-Ladder-Logic | Ladder Logic, Electrical Circuit Diagram, Logic Programming, Create digital artwork to share online and export to popular image formats jpeg, png, svg, and pdf. Mouse over them to see what they do. Figure 1b shows the result. The diagram shows the circuit for switching on or off an electric motor. The highest machine speed attainable is determined by the weighing mechanism.

![Hindi] Basic Plc Bottle Filling Process - Youtube](https://i2.wp.com/i.ytimg.com/vi/8UQOhGp8gqY/mqdefault.jpg “Hindi] Basic Plc Bottle Filling Process - Youtube”)

Hindi] Basic Plc Bottle Filling Process - Youtube, It can be understood by all, with the knowledge of basic principles of drawing. We used proximity switch here because the filling has to be started when the box placed in correct position. So far we have trained it on a few hundred concepts, and we hope to add more over time. Autodraw pairs machine learning with drawings from talented.

Plc Program For Automatic Bottle Rejection System | Plc Ladder Logics, Turing drawings uses machines that operate on a finite 2d grid, where each grid cell can contain one symbol which corresponds to a color value. It is convenient to use and easy to hold for any kind of operator.[4] there are. The workpiece starts moving on the left side and moves to the right when the start button is pressed..

Plc Based Automatic Bottle Filling Project Working - Youtube | Machine Shop Projects, Mechanical Engineering Design, Conveyor System, The speed of packaging is increased thus resulting in more production and business. Create digital artwork to share online and export to popular image formats jpeg, png, svg, and pdf. Caravaggio is a drawing machine able to replicate a digital image using a pen and a continuous line. If you simply change from a cut line to a draw line.

Automatic Bottle Filling System Using Plc - Instrumentationtools, You draw, and a neural network tries to guess what you’re drawing. Create digital artwork to share online and export to popular image formats jpeg, png, svg, and pdf. To develop a filling machine which can fill different volume of bottles on the bases of volume. Figure 1b shows the result. So far we have trained it on a few.

Programmable Logic Controller For Bottle Filling Machine, Machine operates at 60 to 80 packs per minute (ppm) maximum, while a continuous machine can operate up to speeds of 180 ppm. The assembly drawing can be shown in exploded view as shown in the fig. It is convenient to use and easy to hold for any kind of operator.[4] there are. When including a plc in the ladder.